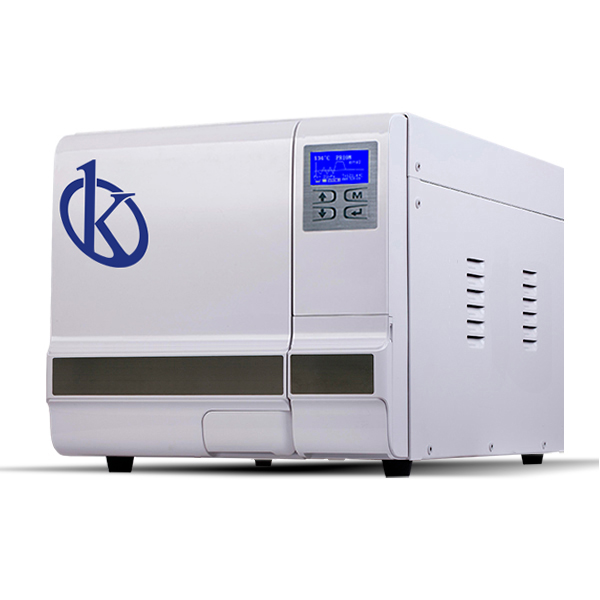

This equipment is indispensable in laboratories, clinics and surgical centers, as it is a fast, compact, versatile sterilizer; It is designed with high technology and cost-effectiveness, while offering operational efficiency and easy maintenance; the advantages of the autoclave lie mainly in the detoxification and sterilization of the material used in surgical treatments or research material; its primary function is as a sterilizing agent by treating water vapor at high temperature to destroy any microorganism found in the material.

The applications of this equipment are so extensive, they are present in different areas and industries; therefore it is essential that the operator know how to handle it, know its parts and especially its maintenance, in this way extend the useful life of the equipment; the autoclave is necessary in any medical field, not only to treat laboratory material but also surgery, inspection or treatment.

Parts of the autoclave

The autoclave parts are essential when sterilizing any product or instrument, there is a variety of autoclave models, in addition to their classification according to their use; but in general, we can present a list of the parts of an autoclave:

- THE KNOB: Exercises a rotating security function to open the door.

- THE DOOR: He’s in charge of sealing the autoclave airtight.

- STAINLESS STEEL CHAMBER: Place where the inner elements of the autoclave will be contained.

- DISTILLED WATER TANK: distilled water container tank.

- WATER TANK USED: Container where the water used in distillation will go.

- LCD DISPLAY: LCD screen that will inform us of the status of the autoclave. Depending on the manufacturer’s model, a different display can be offered.

- CONTROL PANEL: Panel where we will adjust the different parameters.

- MAIN SWITCH: Main switch in charge of turning the autoclave on or off.

- DISTILLED WATER TANK DRAIN KEY: Key responsible for extracting distilled water.

- WATER USED TANK DRAIN KEY: Key responsible for extracting the used water.

- BACTERIOLOGICAL FILTER: Filter to retain bacteria. According to the model they have HEPA filters.

- SAFETY VALVE: Safety valve to seal.

- USB PORT: USB port input for adding connections.

- PRINT PORT: Print port with VGA jack,

- MAIN FUSES: Fuses for distributing electric current.

- ELECTRICITY SUPPLY CABLE: Power take-over.

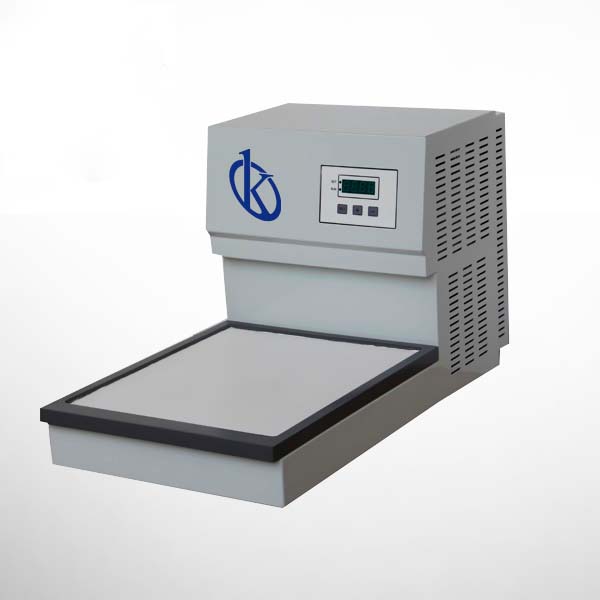

- GRILL: Surface where we deposit the different materials to sterilize.

- GRILL HOLDER: Structure where we place the grills.

- GRILL HANDLE: Handle designed to handle grills safely and efficiently.

Maintenance recommendations for your Autoclave

- In addition to mechanical maintenance and cleaning, it is important to ensure reliability: the importance of proper maintenance, your manufacturer will guide you.

- Timely maintenance ensures the reliability of the appliances.

- Cleaning the chamber and door: Removing and cleaning this waste is a simple and important process that can be done quickly.

- To clean the structures of the autoclave, a damp cloth with demineralized water without detergent should be used, the machine should be off and cold.

- With a moistened sponge clean the surface of the chamber, the bottom and the door, where residues and impurities can accumulate.

- You should clean the tanks regularly to ensure better operation and longer autoclave life.

- Wear gloves throughout the procedure to protect against possible contaminants.

- Using a cloth, or drying paper, clean any deposits and impurities that normally accumulate on the walls and bottom.

- Remove the filters and wash them under a jet stream. After this last operation is finished, reposition the filters and refill the tank.

- It is recommended to extend the life of the equipment use the corresponding water for treatment.

- The autoclave display will show an indication of a problem or failure, do not ignore it, and contact authorized technical personnel.

- The replacement of worn or damaged parts by the technician in a short period of time is necessary precisely because it guarantees the perfect operation of the autoclave, preserving the other parts and the correct operation of the autoclave.

If you want to know the catalog of high-end products that we Kalstein have for you visit us HERE also we assure you that through our online shopping channels that are very easy and viable the best prices of the market, reminding them that we are Company manufacturer of Laboratory Equipment of high level sale.