Centrifuges

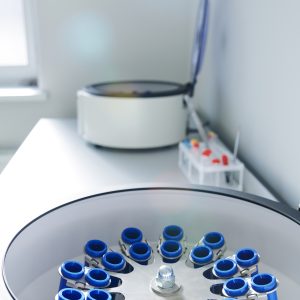

Generally, low speed centrifuges do not exceed 4000 rpm in rotational speed and have a maximum capacity of 2-4l. They are usually handled in laboratories, for primary separation and extraction of large amounts of biological macromolecules and sediments. They have mechanisms made with aluminum fusion, flat type and angle type.

Centrifugal tubes are made of hard glass, hard polyethylene plastic and stainless steel tubes. The centrifuge is equipped with a drive motor, a timer, a regulator (speed indicator). This type of centrifuge is mainly used to collect microorganisms, cellular debris, cells, large organelles, sulfuric acid precipitates and immunoprecipitation.

Types of Centrifuges a Laboratory May Need

Centrifuges, non-refrigerated

They are easy to handle and compact centrifuges, that is, they are small centrifuges and do not have refrigeration so they usually operate at room temperature. Reaches speeds between 4000-5000 rpm. They are used for general laboratory applications, such as separating large particles such as cells, cell suspensions, separating sera, plasma, urine, sperm, among others.

So they are used in the chemical, environmental, pharmaceutical industry, in clinics and laboratories. They can use tilting and fixed-angle rotors.

Refrigerated centrifuges

Centrifugation is a separation technique used to isolate or concentrate suspended particles in a liquid, taking advantage of the different displacement speeds depending on their shape, size or weight when subjected to centrifugal force. Centrifugal force is the force exerted on a body when it rotates around an axis.

This force, whose magnitude is directly proportional to the mass of the body, the radius of gyration and the speed of rotation (or angular), is perpendicular to the axis and tends to move the body away from it. Centrifugal force can accelerate the sedimentation process of particles that tend to do so spontaneously (density higher than liquid), or those that tend to float (density lower than liquid).

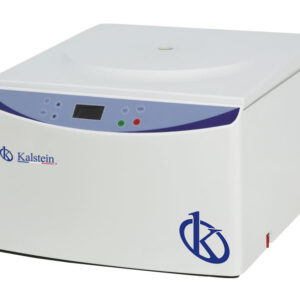

In Kalstein you can find the Ideal centrifuges for your Laboratory

High-speed refrigerated microcentrifuge YR111-5

This multipurpose centrifuge has advanced and intelligent technology. Control by microcomputer, large...

High capacity and high-capacity desktop refrigerated

It has a self-locking device, speed speed safety device, excess temperature safety device, imbalance...

Low speed table centrifuge YR0140-1

The RPMs of the low speed centrifuge are less than 1000R / min, the total centrifugal capacity of up to 3000 ml...

Centrifuge PRP YR469

Several PRP kits are available.A special program is carried out for the PRP Kit.Real-time Speed and RCF conversation....

Our Best Selling Centrifuge

- When the centrifuge is in the pre-cooling state, the cap of the centrifuge must be closed. Once the centrifuge is finished, the rotor must be placed on the test bench and the residual water must be dried in the cavity.

- Rotating head During pre-cooling, the rotary head cover can be placed on the centrifuge platform or on the test bench. Do not screw it into the swivel head, because once it is accidentally activated, the rotary head cover will fly and cause an accident.

- After tightening the threaded lid, be sure to touch the space between the rotor and cover with your fingers. If there is a space, unscrew and press again until the space is confirmed before the centrifuge can be started.

| Model | YR144 |

| Maximum speed | 10,000r/min |

| RCF Max | 5,000 xg |

| Maximum capacity | 0.2ml x 2 x 8 1.5ml / 0.5ml /0.2ml x 6 |

| Noise | <38dB(A) |

| Power supply | 110V/60Hz 220V/50Hz |

| Dimension (W×D×H) | 189 x 161 x 122 (mm) |

| Packing Size (L x W x H) | 330 x 250 x 210 (mm) |

| Net weight | 1kg |

Analysis of the best Centrifuges for your Laboratory

Centrifuge: How to separate samples?

Centrifugation is a process that is carried out in most laboratories and that allows the separation of mixtures...

Use of Centrifuge in Cosmetology

Cosmetology professionals have different types of tools that allow them to create high quality cosmetic products...

Use of Centrifuge for the production of Olive Oil

The centrifuge is a tool used in the production of olive oil to separate the oil from the pulp of the olive. This...

How does a laboratory centrifuge work?

A centrifuge is a piece of equipment that separates particles from a homogeneous solution through rotational...

Catalog of Centrifuge models on offer

-

Mini centrifuge YR143.

-

High-capacity Refrigerated Centrifuge YR118

-

Speed table centrifuge YR0139

Select options This product has multiple variants. The options may be chosen on the product page -

Centrifuge PRP YR469-1 with LCD screen

Select options This product has multiple variants. The options may be chosen on the product page -

Low-speed Refrigerated Centrifuge YR122

-

Centrifuge PRP YR469

Read more -

Speed table centrifuge YR131

Select options This product has multiple variants. The options may be chosen on the product page -

High-capacity Refrigerated Centrifuge YR120

Guide for you to become an expert in laboratory centrifuges

Centrifuge equipment are essential products in a laboratory, we provide guides and recommendations for better use, so you can work as an expert.

What is Centrifuge used for in the Nuclear sector?

Centrifuge is used in the nuclear sector to isolate materials and remove contaminants. This application is one of...

Laboratory centrifuges: care and maintenance

The care and maintenance of these laboratory equipment is indispensable to extend the useful life of the apparatus...

When to use an angular rotor and a horizontal rotor?

This is an indispensable equipment for any laboratory, it is designed for material separation in the areas of molecular...

What are the Applications for High Speed Centrifuge and Low Speed Centrifuges?

Generally, centrifuges are equipment that form rotating movements, managing to separate elements in the samples for study separately, either by decanting or sedimentation. These equipment are used in laboratories, becoming fundamental devices...

Centrifuges in operation

Centrifugation has been the most important process for isolating olive oils since their introduction in the 1960s. It is a mechanical process of separating solid particles of liquids, used to separate high oil content components, not soluble in water. Separation requires the use of a centrifuge, built to allow the flow of liquid through different compartments, separating solids and liquids and allowing separation, based on viscosity and density.

It should be noted that in Kalstein we have the ideal equipment, which has microcomputer control, brushless DC motor, stable operation, low noise level and high speed precision. Touch panel, programmable operation, operation data can be configured according to demands and are stored automatically.

Frequently Asked Questions about Centrifuges

How to know the prices of Centrifuges?

To know the price of Centrifuges we invite you to send us an email with your request through the contact form.

What are the delivery times for Centrifuges?

- If the equipment of your interest is in stock or if it must be manufactured.

- The type of freight you have chosen, this may be; air or sea.

- Equipment in stock:

- Equipment not in stock:

How to make a purchase of Centrifuges?

- By email: [email protected]

- By telephone: +33 (0) 1 78 95 87 02

- E-commerce: Via Kalstein's official website in your country.

How does the warranty work?

At Kalstein, we provide our customers with induction and technical support through new online methods. You can visit our induction videos, technical assistance and guidance provided by a Kalstein team through our YouTube channel (Kalstein English). HERE

Can I request a quote online?

Of course, you can request a quote for the Kalstein team of your interest, directly from our official website. Once you have identified your preferred model, click HERE