Automation of weighing processes with laboratory balances is an essential tool to ensure accurate and precise results; laboratory balances are commonly used in industry to measure and verify the accuracy of materials in the production process.

While the weighing process can be manual, automation reduces human error and improves productivity; automation of weighing processes with laboratory balances is based on the use of computers to track and control weighing information.

Advantages of using laboratory balances

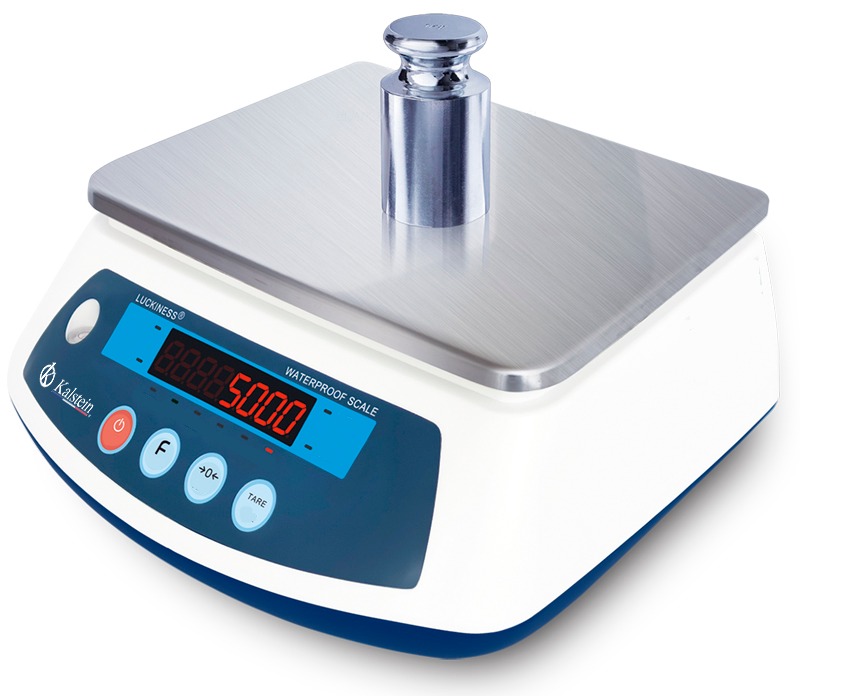

In addition; this reduces human errors by converting weighed or stable product data into numerical results; these devices have features, such as an LCD display to present results, sensors, input and output ports for communication with other devices, as well as motion sensors to control the materials being weighed.

This automation also helps to reduce cycle times and eliminate errors that can arise throughout the process; automating weighing processes with laboratory balances reduces the possibility of human error, resulting in a significant improvement in accuracy and speed of production. It also helps save time and reduce costs.

The advancement of technology provides specialists with digital scales with which they can improve their results

Moreover; the information obtained can also be used for detailed traceability of weighings and determine if there are variations in the values recorded; this is especially useful to ensure that the accuracy of the products is optimal.

Advances in the automation of weighing processes with laboratory balances have made more accurate and precise digital weighing systems available to industry; these digital balances have relieved common manual weighing and provide industry with more accurate results.

The acquisition of digital balances will help the industry to save costs, improve productivity and quality

Digital scales are modern in design and feature accuracy, speed and ease of use; because automation significantly improves accuracy and productivity by linking multiple documents to a single weighing process, it is a good option for reducing human error and improving cycle times.

Advances in the field will also allow the opportunity to customize systems to fit specific user needs; automation of weighing processes with laboratory balances is an essential tool to ensure accurate results and avoid human error.

For Kalstein as a MANUFACTURER it is important for specialists to acquire good quality and low cost balances

You can get sophisticated and top quality equipment in relation to the scales, just press the following link HERE

In Kalstein we offer you the best scales, visit our web page HERE to enjoy great offers and prices without competition, since we are MANUFACTURERS and we can guarantee your effective purchase.