An ELISA microplate washer is a laboratory equipment used to perform washing operations in the ELISA technique. Washing is one of the key stages to be performed when using the ELISA technique. For this purpose, special solutions are used, among the most used is the phosphate buffer solution or PBS.

This phosphate buffer solution is stable for 2 months if stored at 4 °C. It is estimated that 1 to 3 liters of solution is required for washing a microplate. And for each well 300 µl of washing solution is used per cycle. Washing is an operation that can be performed manually, but if you have high demands and if you work with potentially contaminated substances, it is better to use an automated washing equipment

Processes in the ELISA Microplate Washer

The washing processes carried out in the ELISA microplate washer include the following:

- Aspiration from top to bottom: When the suction phase begins, the needles move vertically and the suction starts immediately; these enter the liquid; the process continues until the needles reach the lower maximum position, very close to the bottom of the wells, at which point they stop to avoid sucking air that would necessarily flow over the inner side walls of the wells. This type of aspiration prevents air currents from drying the protein bound on the surface of wells.

- Simultaneous aspiration and dispensing: In this type of washing the washing and aspiration systems operate simultaneously, generating a controlled turbulence inside the well that removes unbound substances during the estimated reaction times.

- Suction from the bottom of the wells: In this system, the suction of the fluid contained in the wells is done by initially positioning the suction needles in a position very close to the bottom, starting at once a suction cycle that is usually controlled by time. This system can suck air if there are differences in tank filling levels.

What considerations should be considered for an ELISA microplate washer to function properly?

For the proper operation of an ELISA microplate washer you need to have:

- A clean, dust-free environment.

- A stable desk. It is advised that it be away from vibration-producing equipment -centrifuges, stirrers-, that it has an adequate size to allow locating, next to the ELISA microplate washer, the complementary equipment required to perform the mentioned technique: analyser, incubator, dispenser and computer.

- An electrical outlet with a good ground pole, connected to an attack that meets the electrical standards and norms implemented in the country or the laboratory. 110 V voltages and 60 Hz frequencies are generally used in American countries.

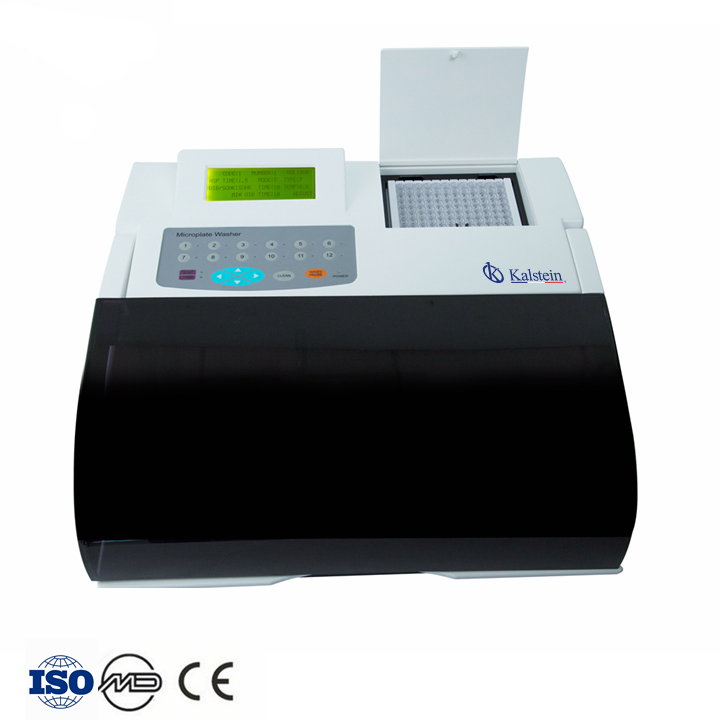

Which ELISA microplate washers exist in Kalstein?

Kalstein is a company MANUFACTURER of laboratory equipment of the highest quality and at the best PRICES in the market, where you can make your purchase confidently and safely, knowing that you have the guarantee and experience of a solid company in the field. Currently we offer two sophisticated microplate washing systems for ELISA, both of which are useful for the proper execution of this technique in your clinical or research laboratory:

Microplate Washer YR05126

- 96-well head

- Single-needle reverse, no suction needle, no lock

- The washing time is less than 30 seconds for a dish.

- Internal centrifuge, no residual liquid, no need to tap the microplate after washing.

- Double plate wash at once, high efficiency.

- Three bottles of 10000 ml high concentration liquid.

- 7″ color touch screen operation, good user experience.

Microplate Washer YR05124 // YR05125

- One or more choice strips of ELISA plate washing keyboard directly

- Minimum residual volume (<1 µ L/well)

- Precision Cv dosage <2%

- Detachable ELISA plate, suitable for cleaning and sterilization of pallets

- Washing programs between 100 groups, adjustable and programmable washing modes

- Cleaning head location adjusted in 5 locations,

- Soak or vibration time schedule

- Temperature: 10’C-30’C wet.; 80%

- Power supply: 220 110VAC ± 10%, 50 60Hz 100W. Automatic waste and distilled water liquid lotion and warning

For more information we invite you to take a look at: HERE