Description

Applicable in the field of protection of biotechnology, pharmaceutical, life sciences and precision electronic products.

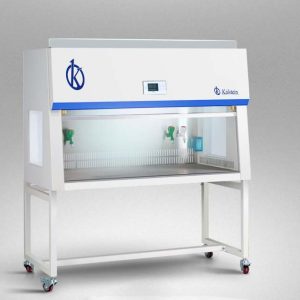

YR Series clean bench combined with perfect airflow mechanical design for the operator to create a partial purification work environment so that experiments can be carried out smoothly.

CE certification, two years warranty period.

Product introduction

- Integrated LCD dot matrix LCD display, real-time display the status of lighting, sterile, air flow and other parameters.

- User-friendly design, with sterilization, lighting, interlock functions to protect the operator from UV light burns and ensure safe operation.

- Wind speed multi-level adjustable, the air volume can be adjusted according to the user.

CLEANFLOW™ clean air technology

- Centrifugal wind wheel low-power motor, based on airflow mechanics principle, arc-shaped large-diameter inlet design to reduce turbulence generated to ensure low noise operation of the system.

- Reasonable duct design, optimized net press box, with micro-mesh design layer outflow wind deflector, convex, no dead ends, to ensure the uniformity and stability of the airflow.

- Standard early-efficient and efficient double-filter, primary filter to avoid airflow dust particles to enter and extend the life of high efficiency filter. High efficiency filter without clapboard HEPA, retention efficiency of 99.99%.

- According to the customer’s requirements, CLEANFLOWTM series with the vertical flow and horizontal airflow

Ergonomically designed

- The front overall tilt design, low noise operation, increase operation comfort.

- Operating room standard with gas water interface, splash-proof power outlet to facilitate the experiments carried out smoothly.

- With weight up and down sliding front door, can be anchored.

- Built-in lighting system to provide the best illumination angle and brightness, reduce visual fatigue.

- On both sides of translucent double-glazed side windows, to enhance the light permeability, and non-convex design of the work area, no death and no spoiler design.

- The platform using an anti-corrosion resistance of SUS304 stainless steel plate forming the front of the arc-shaped design and increase operator comfort.

Modern manufacturing processes

Sheet metal parts use laser cutting and CNC bending technology. Cold-rolled sheets use three line of acidification anti-rust technology. Incubator surface use workmanship of spraying plastics.

Easy to clean

- The early effect of the filter core and the air inlet stencil a shape, facilitate regular on the early effect of filter element folding loading and cleaning.

- The polished design of the work surface as a whole, without pits, no dead ends on both sides, and a minimum of stitching design, easy to clean and disinfect.

Convenient Maintenance

- Removable combination tripod, easy to transport and move, Stand height adjustable.

- Eversion design of the front control panel to facilitate the electrical components, maintenance and replacement.

- In order to make the device able to achieve long-term cleanliness requirements, it is recommended to the early effect of the equipment and high efficiency filter in use for some time to clean or replace.

Technical Specifications

| Model | YR05268 / YR05269 |

| Cleanliness rating | The international ISO 14644.1 standard, CLASS 5 (U.S. Federal 209E, 100 level) |

| Wind Speed | 0.3~0.6m/s(Adjustable) |

| Noise (dB) | ≤62 |

| Vibration half peak | ≤3μm(X、Y、Z direction) |

| High efficiency filter | Efficiency 99.99% |

| Illumination(LX) | ≥300 |

| Work environment | Ambient temperature 10~30℃, Relative humidity |

| below 70%, No obvious vibration and dust around | |

| Overall size(mm) (H×W×D) | 1585×990×735 |

| Inner size(mm) (H×W×D) | 500×830×680 |

| Voltage(V)/ | AC220V/50Hz |

| Power(W) | 440 |

| Net weight (KG) | 110 |

| Shipping weight(KG) | 130 |

| Packing size(mm) (H×W×D) | 1030×1180×855 |