Consistent good processability takes precedence over the obvious requirement of an almost identical coating material composition, which can be very complex. Even if the composition can be assumed to be identical, such a batch may differ fundamentally from the previous delivery during processing or with respect to stability. However, the quality of the coating (also in this case representative of all coating materials) – as well as that of the coating that is subsequently finished – consists in its usefulness or suitability to the needs of the customer, and that:

- Is reproducible from batch to batch

- With constant stability and quality (storage)

The consequence is that classical methods of physical or chemical analysis have very limited utility for quality assurance or for checking the suitability of coatings. It is much more important to test the material in those conditions of application and drying, environmental influences, mechanical stresses, etc. that correspond to the later conditions in reality.

Of course, attempts should be made to speed up testing processes or to carry them out in the form of simulations when a strict replication of the actual situation would simply take too long to produce results or when the respective effects are not understandable at laboratory level.

The importance of viscosity in the processability of paints

Among the many properties of raw materials and coating that influence the results of production and coating, fluidity behavior is undoubtedly one of the most important (also in the case of powder coatings), because its behavior and the effort required for processing and application depend heavily on it. Rheology is the science that deals with the behavior of deformation and the flow of matter. Rheology therefore includes the sub-areas of:

- Theory of elasticity

- Theory of plasticity

- Fluid mechanics

However, as a general rule, the behavior of fluidity cannot be described by a single key value, such as viscosity, because the viscosity of pigmented systems, and in some cases also of transparent layers, usually changes with the level of (mechanical) tension and/or with the tension time. In that sense, viscosity is a property of a liquid that expresses the way it flows or the resistance against it that flows under the influence of force. Representations of flow curves if this is an ideal (Newtonian) flow behavior, it can be defined only by the dynamic viscosity.

Effect of component viscosity on paint

The viscosity of the paint components, namely the base layer and the hardener, must be taken into account in the production process. Moreover, the coating properties, especially viscosity, play an important role when these two components are mixed. Two components can be mixed especially well if they have similar viscosity. If two components have very different viscosities, they are difficult to mix. An illustrative example is the miscibility of viscous honey and fine vinegar with water.

The more the viscosities of the components are separated, the longer the mixing process will take and the homogeneity will be reached. Different viscosities of the base layer and hardener can cause poor mixing. The resulting defects are multiple and often initially attributed to other sources. Possible defects include:

- Points of brightness

- Spots

- The so-called specks

- Loss of corrosion protection

- Other resistance

Effect of viscosity in the application of paint by atomization

The correct characterization of the flow behavior of coating materials plays a decisive role in coating practice. Failure to do so may result in errors in the coating process. These errors are usually not attributed to flow behavior, but to atomization parameters. The consequences may be:

- Leaks

- Weaknesses

- The partial coating of a component

- Insufficient concealment power

Regardless of the output vessel used, this only allows one to determine the output times (in seconds) of the so-called Newtonian fluids and not the actual viscosity (in mPa S) and other rheological properties. Newtonian fluids are materials that have the same viscosity at a constant temperature, regardless of the cutting effort.

The use of the Kalstein brand viscometer to support paint manufacturing

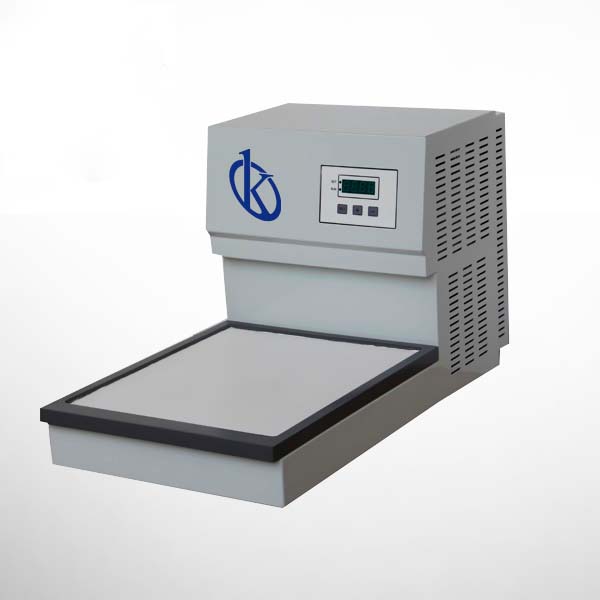

Although viscosity is not the only physicochemical parameter to be evaluated in the preparation of paint, it is one of the most critical, both in terms of raw material and the final product and how to apply it. Therefore, the use of the Kalstein manufacturer’s circulation bath for viscometer allows the performance of viscosity measurements under the required isothermal conditions.

In case of purchase, review price or quote, it can be reviewed on the following page HERE or on the page HERE This equipment is characterized by its high precision in temperature control, its construction in highly durable and resistant materials (stainless steel) and an LCD screen that shows all parameters clearly.